Technical Service

1. Technical Support

Provide customer with the technical consultations and solutions on master alloys used in titanium alloy.

2. Alloy Customization

To specially customize the most suitable master alloy according to the chemical composition of titanium alloy from customer.

Melting temperature, density and size of master alloy customized are closer with matrix

To improve the handling of the pressed electrode and homogeneity of the ingot

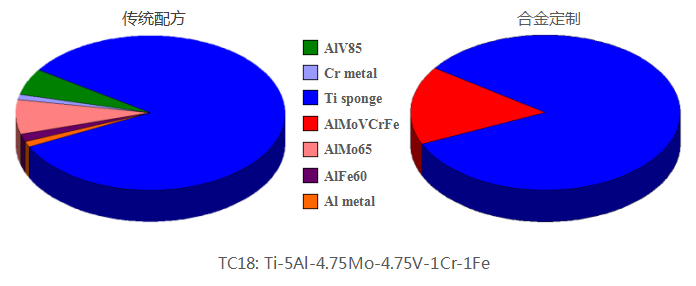

Take TC18 Ti alloy, for example

Raw material | Ratio(wt.%) | |||

Material | Melting temperature(℃) | Density(g/cm3) | Traditional recipe | Alloy customization |

AlV85 | 1890 | 5.14 | 5.59 |

|

Cr metal | 1863 | 7.22 | 1.00 |

|

Ti sponge | 1668 | 4.51 | 83.50 | 83.50 |

AlMoVCrFe 30:29:29:6:6 | 1660 | 4.97 |

| 16.50 |

AlMo65 | 1570 | 5.17 | 7.31 |

|

AlFe60 | 1250 | 4.46 | 1.67 |

|

Al metal | 660 | 2.70 | 0.93 |

|